Elite Restaurant Equipment / Polycarbonate Drinkware / What is Polycarbonate?

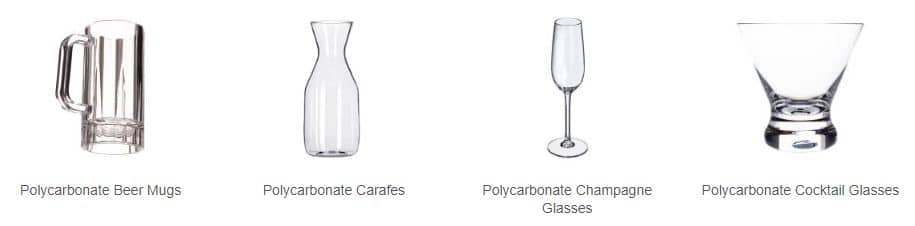

Polycarbonate Drink Ware

What is Polycarbonate?

Polycarbonte is a clear, durable, shatterproof material that is known for its impact on resistance. Polycarbonate made materials are far stronger than those made from acrylics. It's used in applications which demand high performance properties such as bulletproof windows, riot shields, eyewear lenses and more.

This thermoplastic polymer has a highly transparent and refractive index and it has better light transmission characteristics than many conventional glasses. Bringing in the polycarbonate material into the foodservice industry is a unique, elegant, stylish, and smart development which was first manufactured in 2009. Polycarbonate drinkware looks and feels like glass, but is not glass, and most importantly does not break like glass.

Its usage provides a perfect upscale dining experience while entertaining with friends, family, and guests in a safe manner weather your occasion is indoor or outdoor. It also adds to cost-saving in night clubs and bars especially because breakage will never be a concern or turn into a lawsuit for food service operators. The most popular attraction is the crystal clear glass-like material which is un-breakable, hence: Polycarbonate.

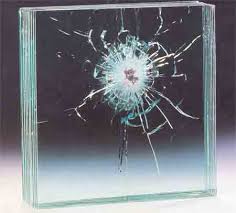

Polycarbonate Fact:

Polycarbonate is the material used for bulletproof glass. This material is used in polycarbonate drinkware

Polycarbonate Definition (Wikipedia):

Polycarbonate is a durable material. Although it has high impact-resistance, it has low scratch-resistance and so a hard coating is applied to polycarbonate drinkware and polycarbonate exterior automotive components. The characteristics of polycarbonate are quite like those of polymethyl methacrylate (PMMA, acrylic), but polycarbonate is stronger and usable over a greater temperature range. Polycarbonate is highly transparent to visible light, with better light transmission than many kinds of glass.

Polycarbonate has a glass transition temperature of about 147 °C (297 °F), so it softens gradually above this point and flows above about 155 °C (311 °F).[1] Tools must be held at high temperatures, generally above 80 °C (176 °F) to make strain- and stress-free products. Low molecular mass grades are easier to mold than higher grades, but their strength is lower as a result. The toughest grades have the highest molecular mass, but are much more difficult to process.

Unlike most thermoplastics, polycarbonate can undergo large plastic deformations without cracking or breaking. As a result, it can be processed and formed at room temperature using sheet metal techniques, such as bending on a brake. Even for sharp angle bends with a tight radius, heating may not be necessary. This makes it valuable in prototyping applications where transparent or electrically non-conductive parts are needed, which cannot be made from sheet metal. Note that PMMA/Plexiglas, which is similar in appearance to polycarbonate, is brittle and cannot be bent at room temperature.

Benefits In Foodservice

Polycarbonate drink ware is clear, durable, shatterproof, indestructible material best known for its impact resistant. Polycarbonate drink ware will not tarnish for 1200 washes. All polycarbonate drink ware is a one piece mold. Because the drink ware is unbreakable, liability is reduced for restaurants, bars, nightclubs, or any other commercial drink service application. Polycarbonate drinkware is often used for outdoor bars as well. Polycarbonate drinkware eliminates repurchasing drinkware and saves business money. Make your investment seek the highest return with polycarbonate drink ware.

Maintenance of Polycarbonate Drinkware

To clean the drinkware; use non-abrasive detergent for best results. Non-abrasive souring pads will help as well. When using a dishwasher to clean polycarbonate drinkware be sure to not exceed 185 degrees. Use water softener in known hard water areas. For best results change water softener every 2-3 months. Do not leave wine, or hard liquor in drinkware for longer than 8 hours for best usability.

Who Manufacturers Make Polycarbonate Drinkware?

Amongst the first manufacturers to make polycarbonate drinkware is Thundergroup Inc. Known for the massive catalog of small ware, dinnerware, specifically for foodservice and hospitality establishments.

When testing began they knew they had something and began going to local bars and speaking with the bar owners about their inception. Bar owners loved the idea since their guests drop glassware which causes: injuries, law suits, and purchasing more glassware.

From inception to testing to serving drinks the polycarbonate indestructible material was a success for drinkware. These days polycarbonate dirnkware is used practically everywhere. Establishments like bars, restaurants, and more. The polycarbonate drinkware has become particularly popular in night clubs, and high end venues.

Other manufacturers that have stepped into the polycarbonate drinkware territory are Carlisle, Cambro, and more.

Related Items:

Polycarbonate Champagne Glasses

Article Submission By: Marcel Bluvstein 9/22/2014